Susan

Susan  2026-01-23

2026-01-23

Articulating Endoscope Applications– Heat Exchanger Inspections

Articulating endoscope uses in aspect industry and home. However, reliable operation of systems that use boiler tubes and or heat exchanges depends greatly on the health of these components and systems. The problem that many operators find is, there is a lot of stress put on these parts because of the nature of their use. These parts are subject to serious damage of oxygen putting and stress. When equipment wear occurs, it needs to be addressed right away, which is why so many people rely on articulating endoscope for inspection of boiler tubes and heat exchanges.

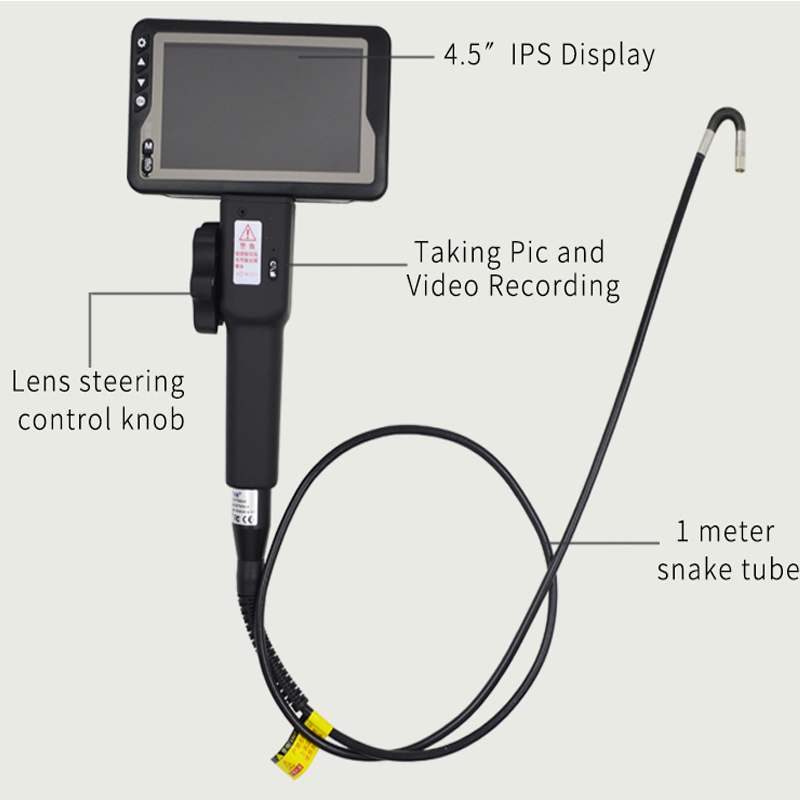

Using an F405S-A, F405S-B, F408S-A, F408S-B, F408S-D Series articulating endoscope allows you to correctly inspect these systems and identify wear, cracks, and leaks. In almost any case, these are the things that happen before catastrophic system failure, and if caught on time, they are completely fixable. Here’s what you need to look for when doing an inspection with your articulating endoscope:

Cracking

In many boiler tubes and/or heat exchanges, cracks can develop at the welds or zones where heat is particularly harsh. The cracking commonly happens below the water level but can become so severe that it leads to equipment failure — this represents a real hazard. Periodic equipment inspection with an articulating endoscope can help you identify and repair any cracking that’s present before major failure.