Susan

Susan  2026-01-23

2026-01-23

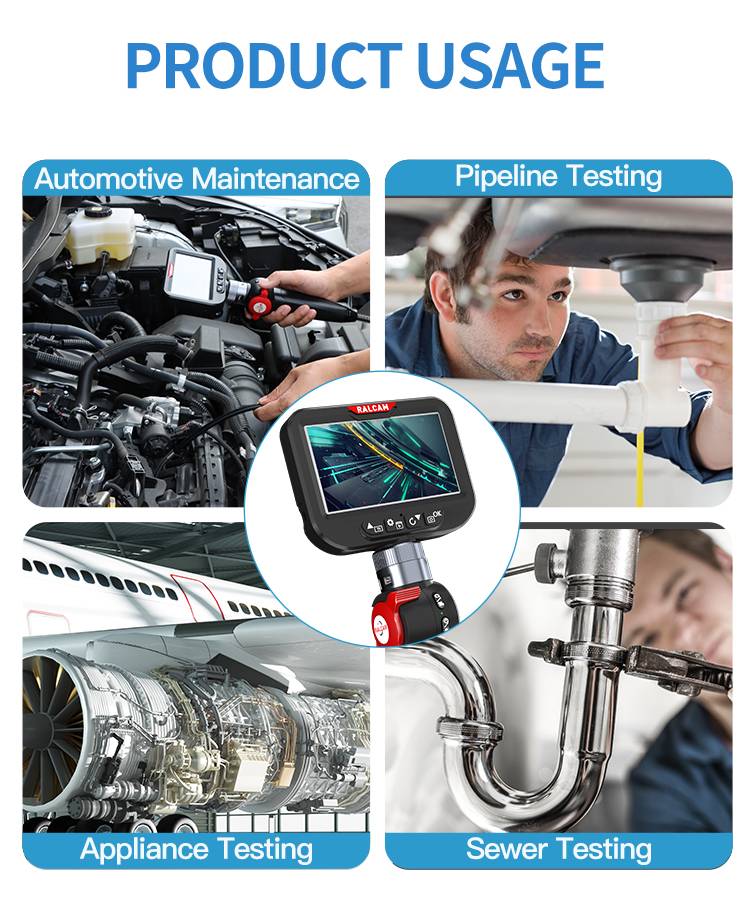

Using inspection cameras to inspect pharmaceutical, food or chemical processing equipment, especially tubing inspection, can help to identify small potential problems before they turn into a major problem. Process tubing requires a smooth flow to pass a fluid or material. Obstructions, corrosion, cracks, pitting, weld integrity in the sidewalls will prevent adequate flow of the process material or liquid. Scheduled inspections of your chiller tubes, boiler or heat exchanger will not only identify small problems but will ultimately minimize downtime because of it not becoming a large problem. As problem solvers we are encouraged not to ignore small problems but to solve them before they become huge problems.

If you continue to ignore the warning signs and not address this small problem, it will absolutely become a huge problem. The same is true of your process piping. The wisdom of solving small problems is by no means new, but perpetually forgotten.

In order to provide the adequate level of quality control in your borescope camera inspection you need to establish proper processes and use correct inspection camera equipment allowing to see inside about any piece of equipment or process tubing without costly and time consuming disassembly and teardown.

Ralcam Borescope specializes in providing borescopes for heat exchanger tube inspections for chillers, condensers, water tube boilers, process piping and evaporators. Non-destructive test techniques including borescopic inspections or push camera inspections, are valuable tools for identifying current conditions and estimating corrosion rates. These NDT Tools identify and document the findings of the process piping inspection, which helps to archive the history and life cycle of the piping.

Condenser tubes are specifically designed to efficiently condense process fluid off the outside of the tube. Cooling tower tubes do exactly what it sounds like they do. A cooling tower is designed to remove heat from a building or facility by spraying water down through the tower to exchange heat into the inside of the building. Air comes in from the sides of the tower and passes through the falling water. Effective use of a borescope can visually determine if there is any pitting, scale formation, corrosion, or accumulation of organic microorganisms inside the support piping. The inspection video scope allows you to capture images and video recording your inspections to track the condition of process tubing over time to allow for early detection of compromised tubes and piping.

Advantages of a Borescope Inspection

The benefits of an internal borescope tube inspection are endless. For starters, it provides additional insight with regard to the current state of the pipe integrity. For example, a borescope inspection prior to the cleaning activities can give an indication of not only the severity of contamination but also leaks or any blockages inside of the tubes.

Although industry standard with inspection cameras will include image capture, video recording, color screen and rechargeable battery packs; Inspection cameras will vary in several key areas:

Probe Diameter

Probe Length

Probe construction

Flexible Probe

Semi Rigid Push Rod

Image Quality

When it comes to selecting the correct pipe camera inspection device consider the details of your specific pipe. What is the inside diameter? What length of pipe are you inspecting? Do you need to negotiate any bends in the piping during the inspection? These are questions that you will need to answer when selecting the right inspection camera for your specific application.

The diameter of the borescope you select must be small enough to enter the pipe that you are inspecting. You will want sufficient room inside your inspection so that the camera can navigate without any restriction or friction due to the diameter of the borescope camera being not small enough. For example, you would not select a borescope that offers a 6mm diameter to inspection a 6mm pipe. Conversely, you do not want a borescope camera that is too small for you inspection area. You would not select that same 6mm borescope camera to perform the inspection of a 6-inch process pipe. Although the borescope camera is small enough to enter the inspection area it will not provide enough lighting to adequately perform an inspection.

Most articulating borescopes will provide a borescope probe that is flexible. These are typically designed with a reinforced steel braided exterior. These devices are frequently used in boiler tube inspections as they provide a small diameter. However, these flexible borescope probes are not conducive to be pushed over a long distance inside of the pipe. If you are inspecting pipes with straight runs with over 20 feet and have ¾ inch diameter or larger, you may choose to select a pipe camera as these typically provide a fiberglass reinforced push rod. These types of inspection cameras are also referred to as push cameras since you can push them over a long distance. A point to make is that even though these types of pipe inspection cameras offer a durable push rod the mini camera and supporting LED’s at the tip are not designed to be used as a clean out tool. These visual inspection tools should not be used to push through clogs or other debris found inside the process piping. These devices can also be found under the shopping category of sewer camera.

Ralcam Borescope has been the market leader in providing borescopes and pipe inspection cameras. Over the years, the borescope products have become increasingly better and tailored to the demands of the customer.Ralcam Borescopes offers a wide variety of remote visual inspection with advance features as well as economy borescopes for entry level applications.