Susan

Susan  2026-01-23

2026-01-23

Borescopes, also called videoscopes, offer an excellent way to inspect the internal components of aviation, as well as other turbine engines. They can help to diagnose problems, but they are also well-placed as part of routine maintenance tasks. Preventive maintenance can be just as important as making repairs as and when they are necessary. In fact, it can be even more important because it helps to prevent problems from developing. This saves time and money and can help to greatly improve safety too.

Borescopes have wide applications and, in addition to being used in aviation and to inspect turbine engines, are also used in the plumbing, HVAC, and manufacturing industries. Using a borescope to check the health of an engine or internal aviation components such as fixed wings and rotor wings makes maintenance and safety checks easier than ever.

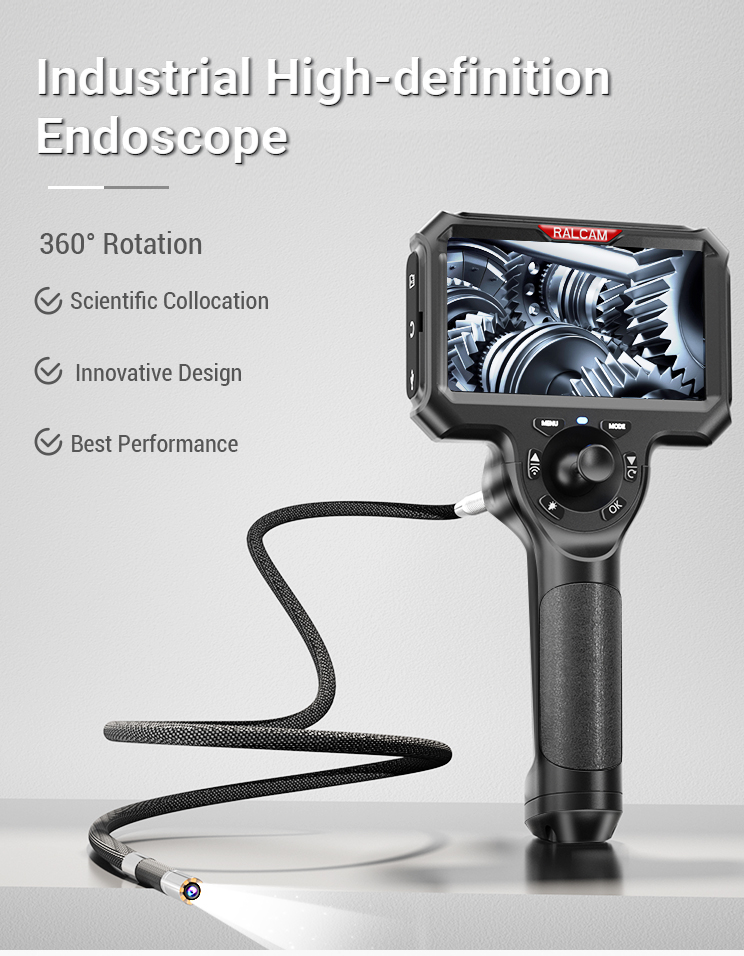

A borescope inspection involves using a camera to look into the inside of an engine or other difficult-to-reach areas. Typically, the borescope will have a length of cable with an LED light on the end that is inserted for visibility. Borescopes can be rigid or flexible, either working in a fixed position or offering the flexibility to snake through narrow and challenging spaces. Flexible borescopes can be particularly useful for inspection engines or other parts that might not be suitable for inspecting with a rigid borescope.

Borescopes are an ideal way to carry out maintenance inspections in a non-damaging way. They can be used to gently inspect different components without affecting their integrity. They can be positioned in any way that’s necessary to get a good view of the part that needs to be inspected. The video can be recorded and many borescope tools also feature Bluetooth to allow images to be shared directly.